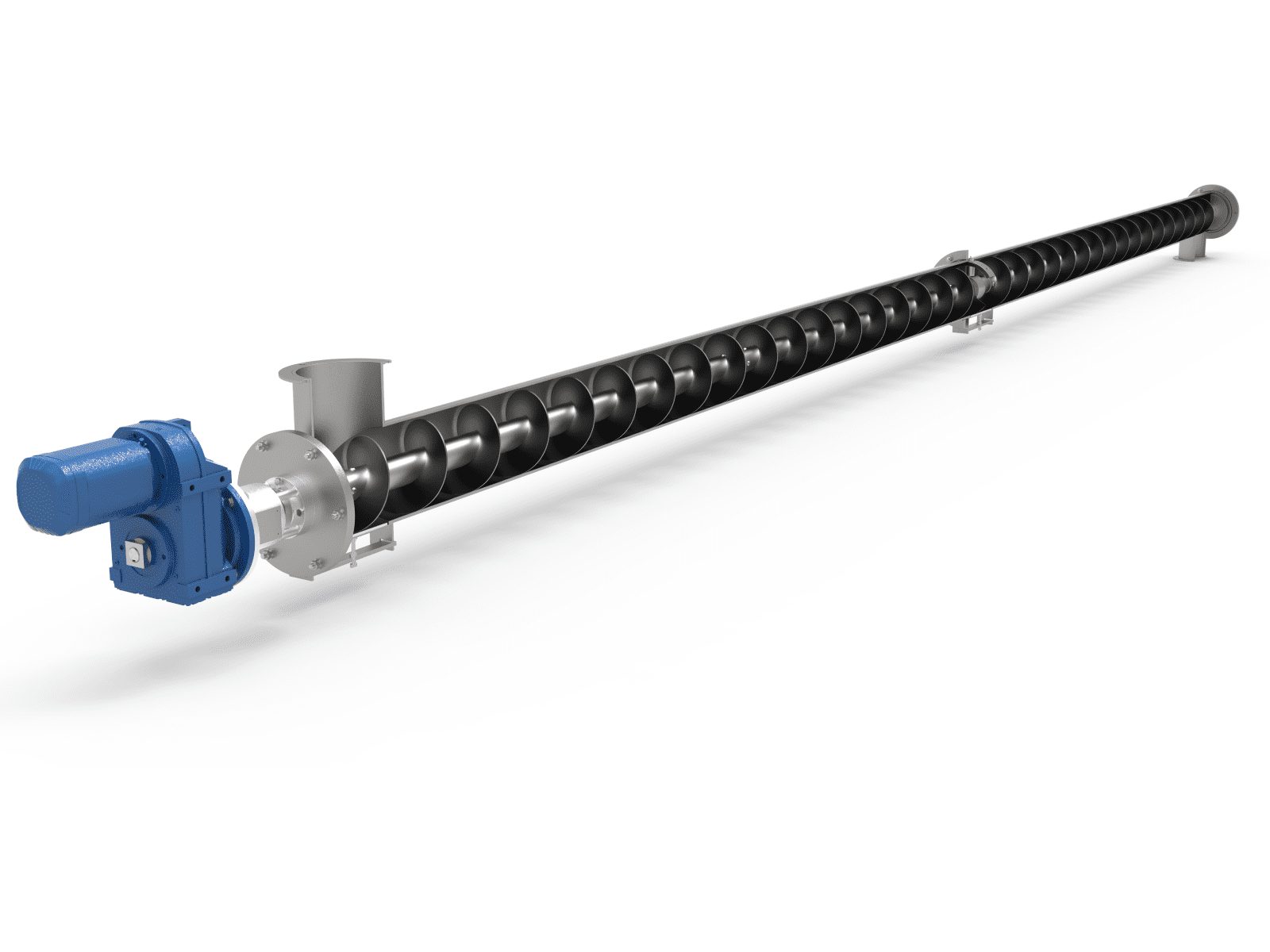

ScrewTech Screw Conveyor

The ScrewTech screw conveyor is intended for use in the non-food industry, for non-aggressive bulk materials.

Today, almost no large-scale production process is complete without it: the screw feeder significantly simplifies the production process, and is also an indispensable mechanism in the construction (transportation of sand, lime, gypsum, siliceous dust, cement, ash and other bulk cargo), glass and mining industries.

It can be used in mechanical engineering to transport dust and shavings from the factory shop premises. In addition to the function of moving bulk materials, the screw feeder * ScrewTech* can act as a dispenser.

It is not recommended for use in the transport of sticky, compacting, and highly abrasive materials.

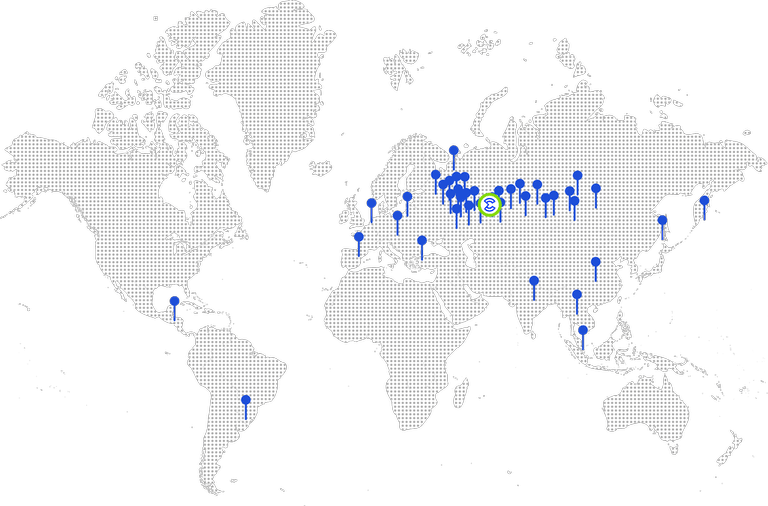

The manufacturer produces a screw feeder with different technical characteristics and capabilities. Before you make a final decision about which screw conveyor to buy, make at least an approximate technical specification and consult with specialists.

Device and characteristics of the ScrewTech screw conveyor

The principle of operation of the screw conveyor is to move dry bulk materials along the chute using a screw. The maximum distance to which the cargo is moved, as a rule, is not limited when moving horizontally, but when moving vertically (inclined), it is limited to 12 meters.

For inclined transport, the maximum angle of inclination is 45 degrees.

The capacity of the line can be up to 90 tons per hour.

Screw conveyors are distinguished by the shape of the body and diameter (this characteristic ranges from 114 to 273 mm on average), the size of which must be consistent and comparable with the purpose and type of cargo.

The direction of rotation of the screw can be right-hand and left-hand. The screw itself is located in a closed casing. (Especially important if the bulk material has a smell and is dusty).

The dimensions of screw feeders * ScrewTech* have constant and variable indicators that depend on the tasks set (the length of the conveyor, the angle of inclination of the line, the specified performance, the properties of the transported material).

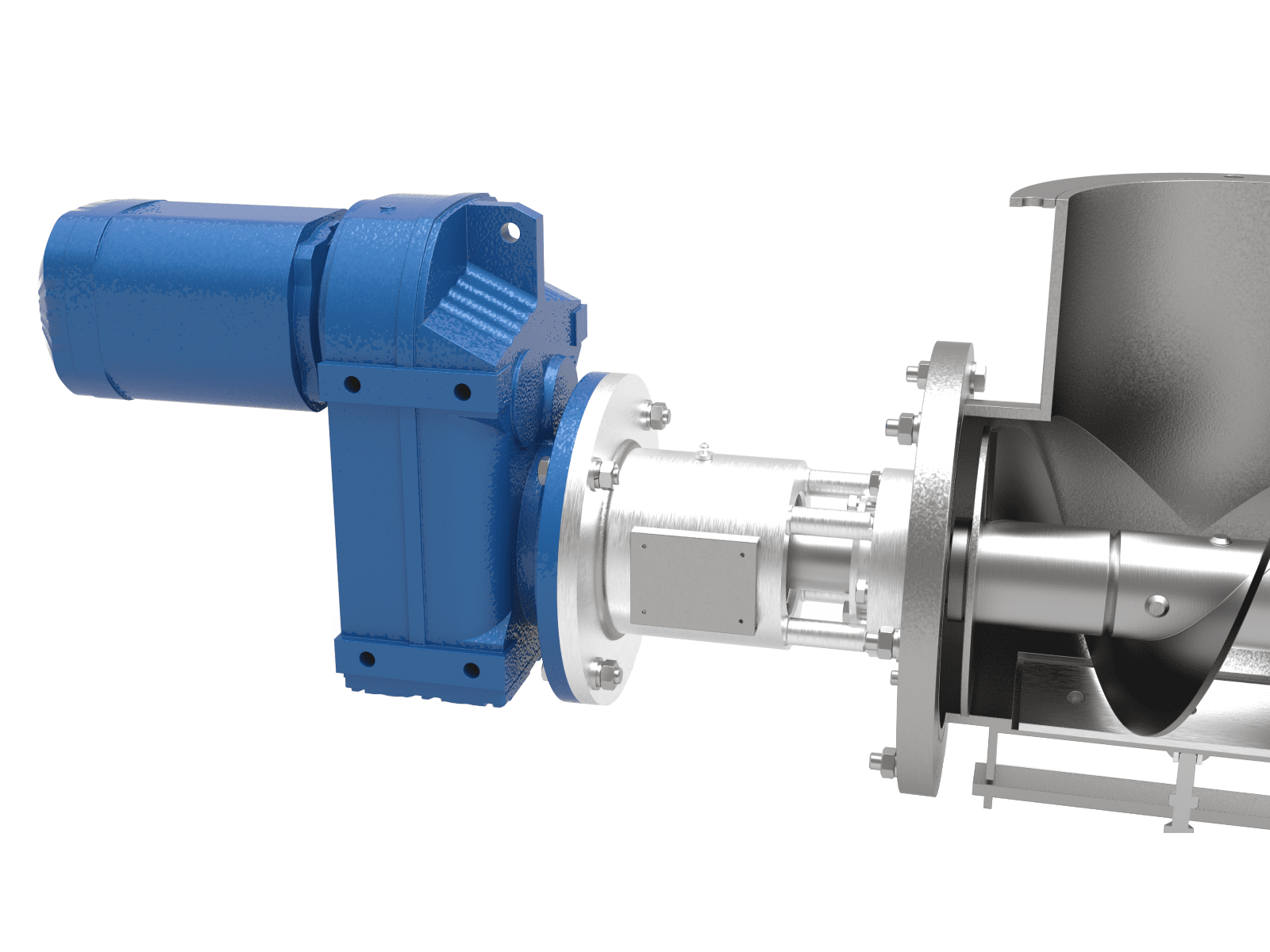

Based on these parameters, the minimum permissible power of the gear motor is also calculated.

The body and the screw pen are made of high-quality steel, which has a positive effect on the strength and wear resistance of the mechanism.